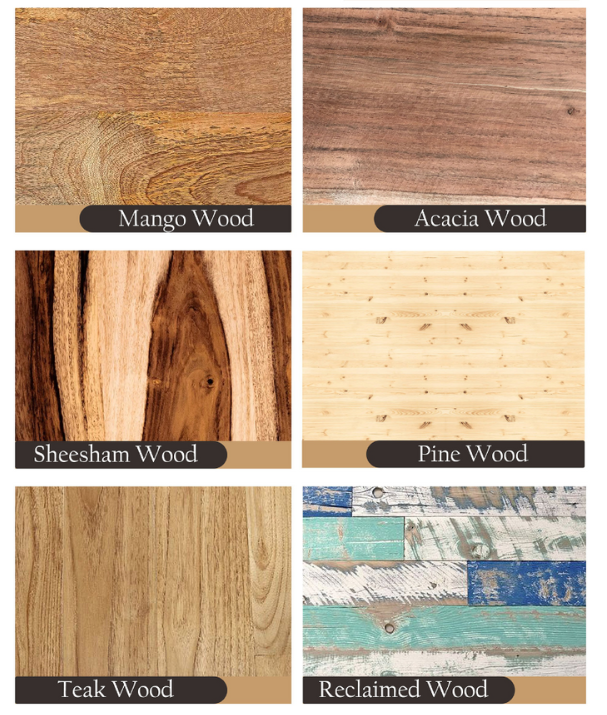

The furniture must always start with high-quality raw materials. Our selection guarantees the longevity, aesthetic appeal, and sustainability of the final product.

Mango Wood Furniture: Considered the most eco-friendly option, mango wood has a distinctive grain pattern which makes it exceptional for rustic and modern styles.

Acacia Wood Furniture: Acacia wood, a dense and highly durable hardwood, is preferred for its rich color and smooth finish.

Rosewood Furniture: This wood is highly sought after for its natural deep hues and resistance to termites. Rosewood furniture brings timeless beauty to any piece.

Mild Steel & Stainless Steel: These metals are corrosion resistant and bring strength to the piece as they are used for frame structures.

Marble, Granite, & Quartz: Stone tops are elegant and durable options for tabletops and countertops which are crafted from these stones.

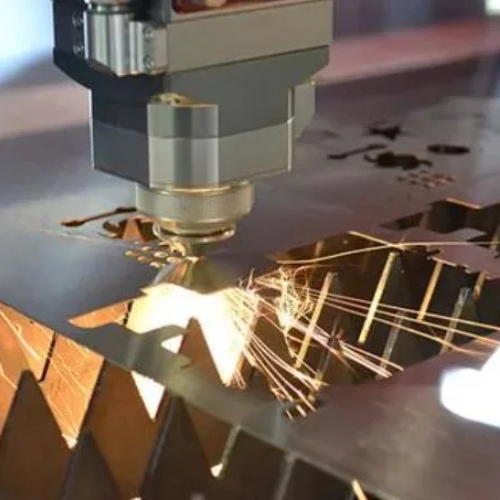

Karma Inc. employs sophisticated machinery, particularly during the production process, where precision and efficiency are of the utmost importance.

CNC Routers – Allows for the exact cutting and shaping of designs.

Planers and Jointers – Provide a smooth, even surface across the wooden workpiece.

Laser Cutting – Employed while cutting elaborate metal components.

Welding Stations – Serves to create strong, seamless joints.

After each respective constituent part is made, they will be manually put together in the form of furniture by expert craftsmen.

Mortise and Tenon Joints – A method reinforced by traditional joinery of adding strength.

Screws and Dowels – Serve as an added support on top of the original guarantee.

Glue Bonding – Employing robust adhesives guarantees enduring durability.

Frame Welding – Enhances structural strength.

Bolt Assembly – Applies for industrial-standard fasteners and bolts to form firm joints.

Sanding contributes to the flawless and smooth appearance of the surface of an object.

Hand Sanding – Accomplishes the delicate nature of detail work.

Machine Sanding: Used for achieving a consistent finish and polish across surfaces.

The overall beauty and durability of the furniture are achieved through the additional finishing work.

Natural Oil Finishes: Bring forth the wood’s natural patterns.

Polyurethane (PU) Coatings: Ensures the wood is covered in protective and shiny coat.

Matte and Glossy Finishes: For better accentuation of specific parts of the room.

Fittings also enhance the aesthetic value of furniture while serving great purpose.

Brass, Wood, and Stainless Steel Knobs and Handles: Different styles and materials are available for these furniture accessories.

Brackets and Hinges: Facilitates smooth furniture operations using high grade furnishings.

All parts are inspected critically for quality before dispatch:

Structural Integrity: Stability and strength of the furniture.

Surface Finish: Inspect keeps surfaces clear of marks.

Rotary Functionality: Opening and closing of doors, drawers, and hinges are ensured to move smoothly.

Dimensions: All are: exact fittings in pre designed spaces.

Optimal condition and undamaged furniture shall be delivered to customers with assured proper packaging.

Carton Packing: These shall be provided with protective 5 ply or 7 ply cartons for transit purposes.

Protective Wrapping:

Bubble Wrap: Provides protection from impact.

Non-Woven Fabric: Protects against surface scratches.

Packing of Stone and Glass: Fragile goods are secured with wooden pallets, and padding.

Furniture is ready for dispatch after packing.

Export Orders: Exports are shipped in export containers, following international shipping regulations.

Domestic Deliveries: Deliveries are made in closed-body trucks to shield them from the elements and road situations.

At Karma Inc. Each process in the manufacturing of our mango wood furniture alongside our acacia wood furniture, rosewood furniture, and vintage wooden furniture is done with precision to ensure that we exceed quality standards of our customers. From modern living room centerpieces to heirloom classic pieces, our furniture is meticulously constructed to endure the test of time while adding elegance and functionality to homes across the globe.